WHAT WE OFFER

We provide the process of filling product in molded packaging which made from raw materials that suit to customer’s product.

HIGH BARRIER PROPERTY OF FLEXIBLE PACKAGING

Composed of special materials shielding the product against moisture, temperature variations, oxygen, light and biological microorganisms reduces the risk of degradation.

CERTIFIED PRODUCTION SITE

Manufacture under GMP/ISO standards by using state-of-the-art technology.

MODERN DESIGN

Easy-to-squeeze design with up to six colors variation. Suitable for on-the-go lifestyle.

STRICT QUALITY CONTROL

Analysis of physical and microbial control of packaging and bulk product.

HIGH PRECISION & LIGHTWEIGHT

High filling precision, lightweight, non-breakable packaging.

ECO-FRIENDLY PACKAGING

Biomass material. 30.5% reduction of plastic use.

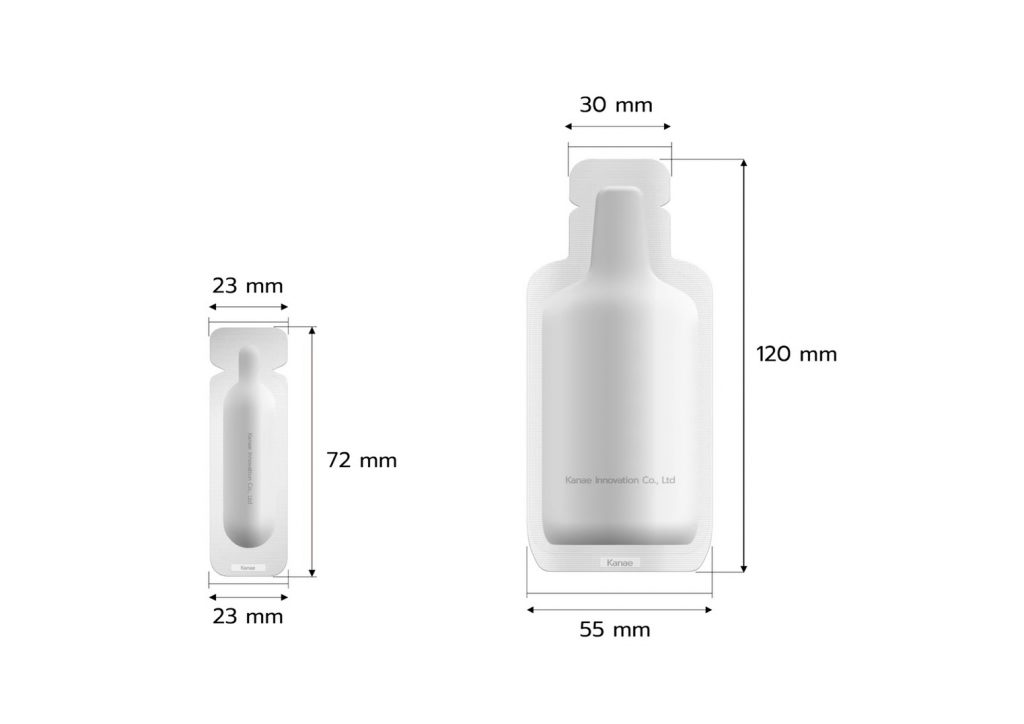

PRODUCT SPECIFICATION

Appearance :

HOMOGENOUS & NO ABRASIVE PARTICLES

Viscosity :

LESS THAN 200,000 CP FILLING WEIGHT: DEPEND ON DENSITY OF BULK PRODUCT AND DESIGN PH: 2-7

Filling weight :

DEPEND ON DENSITY OF BULK PRODUCT AND DESIGN PH: 2-7

Small size :

ONE SIDE FORMING MAXIMUM 1.0 G.

TWO SIDE FORMING MAXIMUM 2.0 G.

Large size :

ONE SIDE FORMING MAXIMUM 10.0 G.

TWO SIDE FORMING MAXIMUM 17.0 G

Every product from KANAE Innovation will be conducted the stability test in Thailand and compatibility test at Packaging Technical Development Center (PTDC) in Japan to assure shelf life and quality of the product.

production timeline

• Appearance

• Seal strength

• Lamination strength

• Pressure test

• Tearing test form the notch

Stability test of product conducted in Thailand 🇹🇭

Can be designed up to 6 colors

Ship in bulk product by customer Microbial test

• Production site

• Bulk product

• Reel of film

Qualitu control

• Pressure test

• Seal check test

• Weight variation test

• Microbial test of finished product